By Andy daga masana'antar Baiyear

An sabunta ta Nuwamba 1, 2022

Har yanzu ba a sami cikakkiyar ma'ana ba.Bisa ga ma'anar a cikin mujallar ƙwararrun ƙwararrun ƙasashen waje, ana iya bayyana shi azaman: Ƙarfe mai cikakken tsari ne na aikin sanyi don faranti na bakin ciki (yawanci ƙasa da 6mm), gami da shear, naushi / yanke / haɗawa, nadawa, walda, riveting, splicing. , forming (kamar jikin mota), da dai sauransu. Babban fasalinsa shine cewa kaurin sashi ɗaya ɗaya ne.

Sheet karfe yankan ne mai muhimmanci tsari ga forming sheet karfe kayayyakin.Ya hada da gargajiya yankan, blanking, lankwasawa forming da sauran hanyoyin da kuma tsari sigogi, kazalika da daban-daban sanyi stamping mutu Tsarin da tsari sigogi, daban-daban kayan aiki ka'idodin aiki da kuma aiki hanyoyin, kazalika da sabon stamping fasaha da sabuwar fasaha .

Ga kowane ɓangaren ƙarfe na takarda, yana da takamaiman tsari, wanda shine abin da ake kira tsarin fasaha.Tare da bambance-bambance a cikin tsarin sassa na takarda, tsarin fasaha na iya zama daban-daban, amma jimlar ba ta wuce maki masu zuwa ba.

1. Zana da zana ɓangaren zanen sassan ƙarfen sa, wanda kuma aka sani da ra'ayoyi uku.Ayyukansa shine bayyana tsarin sassan ƙarfensa ta hanyar zane.

2. Zana zane mai buɗewa.Wato buɗe wani sashe mai sarƙaƙƙiya tsari zuwa wani yanki mai faɗi.

3. Barci.Akwai hanyoyi da yawa na bangaranci, musamman ta hanyoyi masu zuwa:

a.Yanke injin shearing.Shi ne a yi amfani da na'ura mai sassaƙa don yanke siffar, tsayi da nisa na zane mai faɗi.Idan akwai naushi da yankan kusurwa, to sai a juya na'urar buga naushi don haɗa nau'in mutun da yankan kusurwa don samarwa.

b.Punch blanking.Za a yi amfani da naushi don naushi tsarin ɓangaren lebur bayan an buɗe sassan a kan farantin a cikin matakai ɗaya ko fiye.Yana da fa'idodin gajeriyar sa'o'i na mutum, ingantaccen inganci, kuma yana iya rage farashin sarrafawa.

c.Farashin NCCNC.Lokacin NC blanking, mataki na farko shine rubuta shirin CNC machining.Shi ne a yi amfani da software na shirye-shirye rubuta zana fadada zane a cikin wani shirin da NC CNC machining inji iya gane.Bari ta bi waɗannan shirye-shiryen mataki-mataki a kan farantin ƙarfe A Kunna, fitar da sifar sassan sassa.

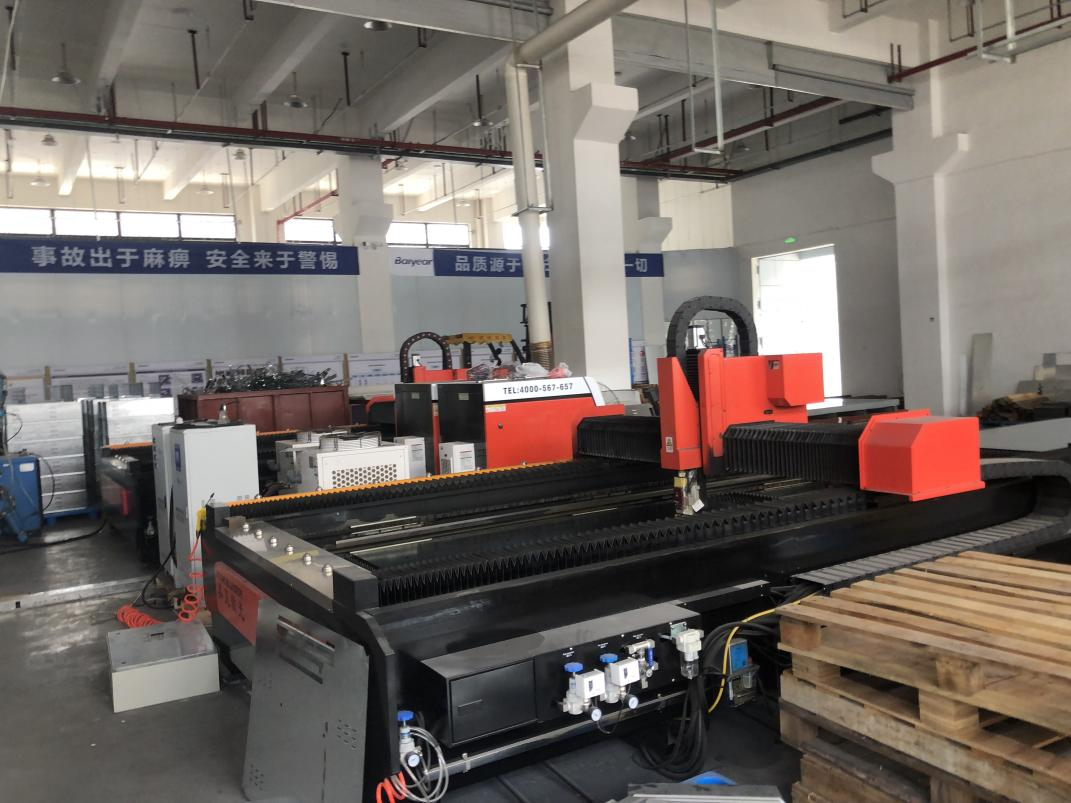

d.Laser yankan.Yana amfani da hanyar yankan Laser don yanke fasalin tsarin sassan sa akan farantin ƙarfe.

4. Fizgewa da bugawa.Har ila yau ana kiran flanging rami, wanda shine a zana rami mai girma a kan ƙaramin ramin tushe, sannan a taɓa ramin.Wannan zai iya ƙara ƙarfinsa kuma ya guje wa zamewa.Gabaɗaya ana amfani da shi don sarrafa ƙarfe na takarda tare da kauri mai kauri na bakin ciki.Lokacin da kauri farantin yana da girma, kamar kauri na farantin sama da 2.0, 2.5, da sauransu, zamu iya matsa kai tsaye ba tare da flanging ba.

5. sarrafa naushi.Gabaɗaya, ana yin amfani da naushi da yankan kusurwa, ƙulle blanking, ƙwanƙwasa ƙwanƙwasa, naushi da tsagewa, naushi da sauran hanyoyin sarrafawa don cimma manufar sarrafawa.Yin aiki yana buƙatar gyare-gyare masu dacewa don kammala aikin.Akwai ƙwanƙwasa ƙwanƙwasa don naushi convex ƙwanƙwasa, da tsagewar da ke haifar da gyaggyarawa don naushi da tsagewa.

6. Matsa lamba riveting.Dangane da masana'antar mu, ana yawan amfani da ingantattun ƙwanƙwasa ƙwanƙwasa, matsi na goro, screws ɗin matsa lamba, da sauransu.Riveted to sheet karfe sassa.

7. Lankwasawa.Lankwasawa shine a ninka 2D lebur sassa zuwa sassa 3D.Sarrafa shi yana buƙatar injin lankwasawa da kuma mutuƙar lanƙwasawa don kammala aikin.Hakanan yana da wasu jerin lanƙwasawa.Ninki na farko wanda ba ya tsoma baki zai haifar da na ƙarshe wanda ke tsoma baki.

8. Walda.Welding shine a dunƙule sassa da yawa tare don cimma manufar sarrafawa ko walda gefen gefen sashi ɗaya don ƙara ƙarfinsa.Hanyoyin sarrafawa gabaɗaya sun haɗa da: CO2 gas kariya waldi, argon baka waldi, Spot waldi, robot waldi, da dai sauransu Zaɓin waɗannan hanyoyin walda sun dogara ne akan ainihin buƙatu da kayan aiki.Gabaɗaya magana, ana amfani da walda mai kariya ta CO2 don waldawar farantin ƙarfe;Ana amfani da waldawar argon don walƙiya farantin aluminum;Ana amfani da walda na mutum-mutumi a cikin kayan aiki Ana amfani da shi lokacin da sassan suke da girma kuma kabu na walda yana da tsawo.Irin su walda na hukuma, ana iya amfani da walda na mutum-mutumi, wanda zai iya ceton ayyuka da yawa da inganta ingantaccen aiki da ingancin walda.

9. Maganin saman.Surface jiyya kullum hada phosphating film, electroplating multicolored tutiya, chromate, yin burodi Paint, hadawan abu da iskar shaka, da dai sauransu. Phosphating film ne kullum amfani ga sanyi-birgima zanen gado da electrolytic zanen gado, da kuma aikinsa shi ne yafi gashi saman na kayan.Ana amfani da fim mai kariya don hana oxidation;na biyu shine don inganta manne da fentin toyasa.Electroplating m tutiya ne gaba ɗaya amfani da surface jiyya na sanyi-birgima faranti;chromate da hadawan abu da iskar shaka ana amfani da su gabaɗaya don jiyya na saman faranti na aluminum da bayanan martaba na aluminum;takamaiman yanayin sa Zaɓin hanyar sarrafawa yana ƙaddara bisa ga bukatun abokin ciniki.

10. Majalisa.Abin da ake kira taro shine a haɗa sassa da yawa ko abubuwan haɗin gwiwa tare ta wata hanya don yin su cikakke.Ɗaya daga cikin abubuwan da ya kamata a kula da shi shine kariyar kayan, ba tabo da kullun ba.Haɗawa shine mataki na ƙarshe na kammala wani abu.Idan ba za a iya amfani da kayan ba saboda raguwa da raguwa, yana buƙatar sake yin aiki da sake yin aiki, wanda zai ɓata lokaci mai yawa na aiki kuma ya kara yawan farashin abu.Don haka, ya kamata a ba da kulawa ta musamman ga kariyar kayan.

Lokacin aikawa: Nuwamba-29-2022