Menene nau'ikan kayan gyaran allura?

Yin gyare-gyaren allura wani tsari ne na masana'antu wanda ya ƙunshi allurar narkakkar a cikin rami don samar da siffar da ake so.Ana iya amfani da gyare-gyaren allura don ƙirƙirar kayayyaki daban-daban, kamar sassa na filastik, abubuwan ƙarfe, na'urorin likitanci, da ƙari.Koyaya, ba duk kayan sun dace da gyaran allura ba.Za mu tattauna nau'ikan kayan gyare-gyaren allura da kaddarorinsu, fa'idodi, da rashin amfani.

Nau'in allura kayan gyare-gyare

Akwai nau'ikan kayan gyare-gyaren allura da yawa, amma ana iya rarraba su gabaɗaya zuwa rukuni huɗu: thermoplastics, thermosets, elastomers, da ƙarfe.

Thermoplastics

Thermoplastics kayan aiki ne waɗanda za a iya narkar da su akai-akai da ƙarfafa ta hanyar dumama da sanyaya.Su ne mafi yawan nau'in kayan gyare-gyaren allura, wanda ya kai kusan kashi 80% na kasuwa.Thermoplastics suna da babban sassauci, karko, da sake amfani da su.Wasu misalan thermoplastics sune:

- Polyethylene (PE): Wani abu mai rahusa wanda ke da kyakkyawan juriya ga sinadarai, danshi, da tasiri.Ana amfani da shi sosai don marufi, kwantena, kayan wasan yara, da bututu.

- Polypropylene (PP): Abu ne wanda ke da tsayin daka, ƙarfi, da juriya mai zafi.Ana amfani da shi don sassan mota, na'urorin likitanci, daki, da na'urori.

- Polyvinyl chloride (PVC): Wani abu ne wanda ke da ingantaccen rufin lantarki, jinkirin harshen wuta, da yanayin yanayi.Ana amfani da shi don igiyoyin lantarki, bututu, kayan aiki, da shimfidar bene.

- Polystyrene (PS): Abu ne wanda ke da tsabta mai kyau, tsauri, da kwanciyar hankali.Ana amfani dashi don kofuna, faranti, kayan yanka, da marufi.

- Acrylonitrile butadiene styrene (ABS): Wani abu ne wanda ke da ƙarfin tasiri mai kyau, tauri, da ƙarewar saman.Ana amfani dashi don gidaje, kwalkwali, kayan wasan yara, da kayan kida.

- Nylon: Abun da ke da juriya mai kyau, juriya, da kaddarorin inji.Ana amfani da shi don gears, bearings, bushings, da fasteners.

Thermosets

Thermosets kayan aiki ne waɗanda ke jujjuya halayen sinadarai lokacin zafi kuma suna samar da siffa ta dindindin wacce ba za a iya narkewa ko sake fasalinta ba.Thermosets suna da babban kwanciyar hankali na thermal, juriyar sinadarai, da ƙarfin injina.Wasu misalan thermosets sune:

- Epoxy: Abun da ke da kyakkyawan mannewa, rufin lantarki, da juriya na lalata.Ana amfani dashi don sutura, adhesives, laminates, da composites.

- Phenolic: Wani abu ne wanda ke da tsayin daka na zafi, jinkirin harshen wuta, da tauri.Ana amfani da shi don maɓallan wutar lantarki, kwasfa, matosai, da riguna.

- Polyester: Abu ne wanda ke da kyakkyawan sassauci, karko, da yanayin yanayi.Ana amfani da shi don tarkacen jirgin ruwa, jikin mota, tankuna, da bututu.

- Urea formaldehyde: Kayan da ke da ƙarancin farashi, babban tauri, da kwanciyar hankali mai kyau.Ana amfani dashi don maɓalli, maɓalli,

hannunka, da furniture.

Elastomers

Elastomers kayan aiki ne waɗanda za'a iya shimfiɗawa ko matsawa kuma su koma ga asalinsu lokacin da aka cire ƙarfin.Elastomers suna da babban elasticity,

resilience, da shock absorption.Wasu misalan elastomers sune:

- Silicone: Wani abu wanda yana da kyakkyawan juriya na zafi, juriya na ozone, da kuma biocompatibility. Ana amfani dashi don hatimi, gasket, tubing, da na'urorin likita.

- Rubber: Wani abu ne wanda ke da juriya mai kyau, juriya ga gajiya, da damping vibration. Ana amfani dashi don taya, belts, hoses, da grommets.

- Thermoplastic elastomers (TPEs): Wani abu ne wanda ya haɗu da kaddarorin thermoplastics da elastomers. Ana iya sarrafa shi kamar thermoplastics, amma yana da sassauci da elasticity na elastomers. Ana amfani dashi don grips, bumpers, tabarma, da hatimi.

Karfe

Karfe kayan aiki ne da ke da babban aiki, yawa, da kuma narkewa. Yawancin lokaci ana allura su a cikin wani tsari ta hanyar amfani da tsari na musamman da ake kira karfen allura (MIM). mold.The molded part ne mai zafi da cire binders da sintered don samar da wani m karfe part.MIM iya samar da hadaddun siffofi da high daidaito, surface gama, da inji Properties.Wasu misalan karafa da za a iya amfani da MIM ne:

- Bakin Karfe: Wani abu ne wanda ke da juriya mai girma, ƙarfi, da taurin. Ana amfani da shi don kayan aikin tiyata, dasa hakori, kayan ado, da agogo.

- Titanium: Wani abu wanda yana da babban ƙarfin-zuwa-nauyi rabo, bio-daidaituwa, da juriya na zafi. Ana amfani dashi don abubuwan haɗin sararin samaniya, kayan wasanni, dasa hakori, da na'urorin likitanci.

Iron: Abu ne wanda ke da ƙarancin farashi, kaddarorin maganadisu, da juriya. Ana amfani dashi don sassa na kera motoci, kayan aikin wutar lantarki, gears, da bearings.

Kammalawa

Yin gyare-gyaren allura wani tsari ne mai ma'ana wanda zai iya samar da kayayyaki iri-iri ta amfani da nau'o'in kayan aiki daban-daban.Kowane nau'in kayan yana da halayensa,

Abũbuwan amfãni, da rashin amfani.Saboda haka, yana da mahimmanci don zaɓar kayan da ya dace don takamaiman aikace-aikacen da buƙatun ƙira. Hakanan za'a iya haɗa gyare-gyaren allura tare da wasu matakai, irin su saka gyare-gyare, overmolding, da haɗin gwiwa, don ƙirƙirar abubuwa masu yawa. ko samfuran launuka masu yawa. Yin gyare-gyaren allura hanya ce mai sauri, inganci, kuma mai tsada don kera samfuran inganci.

Menene gyaran allura?

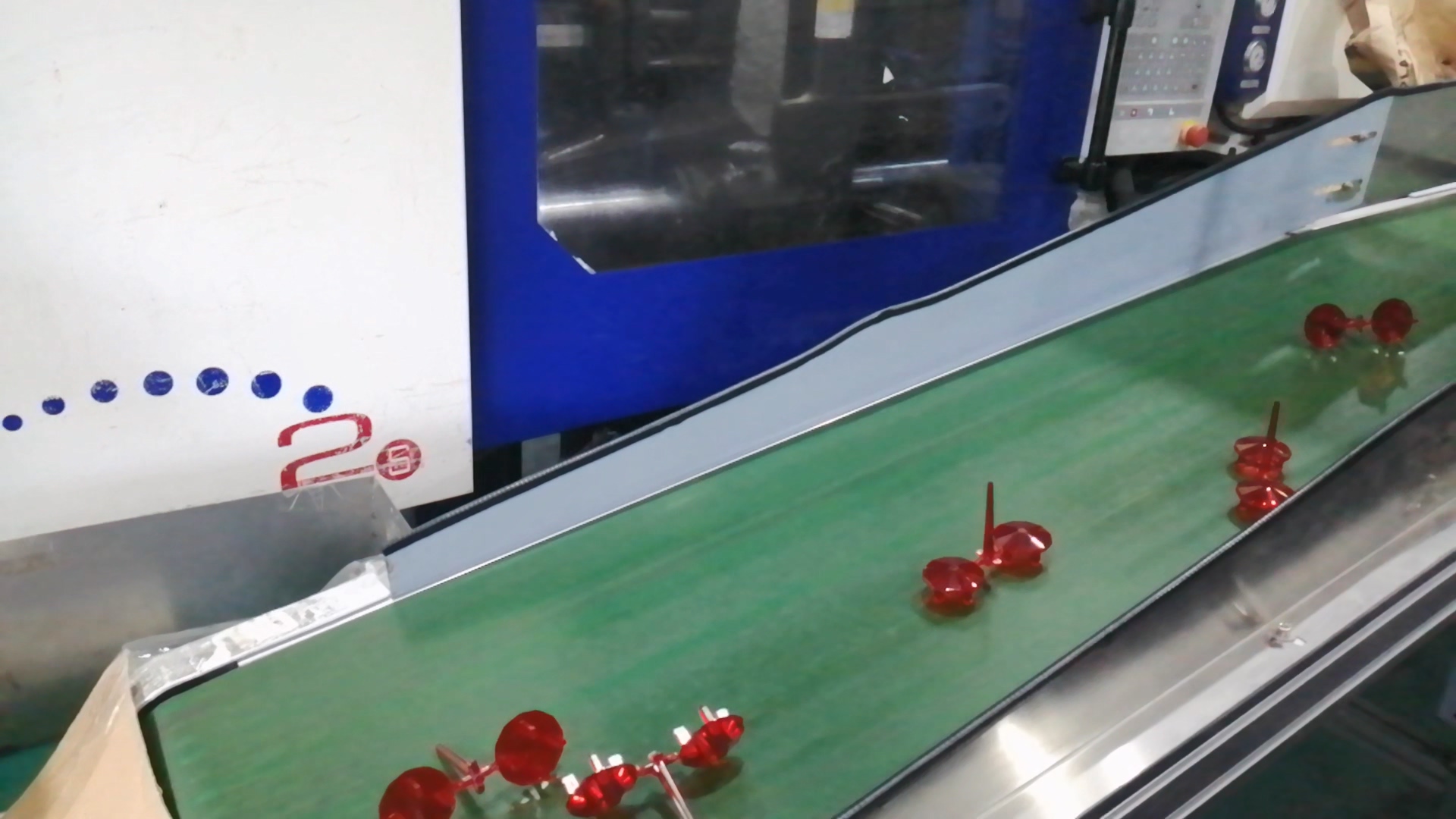

Yin gyare-gyaren allura wani tsari ne na masana'antu wanda ke samar da sassa na filastik ta hanyar allurar narkakkar a cikin wani nau'i.Tsarin ya ƙunshi manyan matakai guda huɗu: matsawa, allura, sanyaya da fitarwa.

Matsawa: Tsarin ya ƙunshi rabi biyu, da ake kira rami da ainihin, waɗanda ke manne da naúrar matsawa.Ƙungiyar matsawa tana riƙe da ƙura a rufe ƙarƙashin matsin lamba yayin allura da matakan sanyaya.Ƙarfin maƙarƙashiya ya dogara da girman da siffar ɓangaren, da kuma kayan da aka yi amfani da su.

Allura: Kayan filastik, yawanci a cikin nau'i na pellets ko granules, ana ciyar da su a cikin ganga mai zafi, inda aka narkar da shi kuma a gauraye ta hanyar juyawa mai juyawa.Har ila yau, dunƙule yana aiki azaman mai shigar da ruwa, yana tura robobin da aka narkar da shi a cikin injin ta cikin bututun ƙarfe.Ana sarrafa saurin allura, matsa lamba da zafin jiki don tabbatar da cewa kayan sun cika ƙirar gaba ɗaya kuma daidai.

Sanyaya: Narkar da robobin da ke cikin kwandon ya fara yin sanyi da ƙarfi, yana ɗaukar siffar ɓangaren.Lokacin sanyaya ya dogara da kauri da lissafi na sashi, da kuma kayan kayan.A lokacin wannan mataki, ƙirar ta kasance a rufe kuma tana ƙarƙashin matsin lamba don hana raguwa ko nakasa.

Fitarwa: Bayan sashin ya yi sanyi sosai, ana buɗe ƙirar kuma ana fitar da sashin ta hanyar da ake kira tsarin fitarwa.Tsarin fitarwa na iya zama fil, ruwan wukake ko jirage masu saukar ungulu waɗanda ke tura ɓangaren daga cikin ƙirar.Sannan ana cire sashin daga injin kuma a duba ingancinsa.

Yin gyare-gyaren allura wani tsari ne mai mahimmanci da inganci wanda zai iya samar da sassa masu rikitarwa da inganci a cikin adadi mai yawa kuma tare da ƙananan sharar gida.Ana amfani da shi sosai a masana'antu daban-daban, kamar motoci, likitanci, kayan masarufi, kayan lantarki da ƙari.

Menene mahimmanci da rawar allura molds?

Yin gyare-gyaren allura shine tsarin masana'anta da aka yi amfani da shi sosai wanda zai iya samar da sassa na filastik tare da sifofi masu rikitarwa da madaidaici.Yin gyare-gyaren allura ya ƙunshi allurar narkakkar robobi a cikin wani rami mai sanyi, inda zai yi sanyi kuma ya daidaita zuwa siffar da ake so.Ƙarfe ko yumbu yawanci ana yin shi ne da ƙarfe ko yumbu, kuma ana iya tsara shi don samar da sassa da yawa a lokaci ɗaya.

Muhimmanci da rawar gyare-gyaren allura suna da mahimmanci a masana'antu da yawa, kamar motoci, likitanci, sararin samaniya, na'urorin lantarki masu amfani, da ƙari.Yin gyaran allura na iya bayar da fa'idodi da yawa, kamar:

- Haɓaka haɓaka mai girma: gyare-gyaren allura na iya samar da adadi mai yawa na sassa a cikin ɗan gajeren lokaci, tare da ƙarancin sharar gida da tarkace.Injin gyare-gyaren allura na iya ci gaba da aiki, kuma ana iya sarrafa su don rage farashin aiki da kurakuran ɗan adam.

- Babban inganci da daidaito: Yin gyare-gyaren allura na iya samar da sassa tare da daidaiton girman girman girma da ƙarewar saman, kazalika da kaddarorin iri da aiki.Gyaran allura kuma na iya rage lahani da bambance-bambance a cikin samfurin ƙarshe, ta hanyar sarrafa zafin jiki, matsa lamba, da saurin aikin allurar.

- Sassautun ƙira: gyare-gyaren allura na iya samar da sassa tare da hadaddun geometries, cikakkun bayanai, da launuka masu yawa ko kayan.Yin gyare-gyaren allura kuma na iya ɗaukar sauye-sauye a ƙira ko ƙayyadaddun sassa, ta hanyar gyaggyara rami ko yin amfani da kayan filastik daban-daban.

- Tasirin farashi: Gyaran allura na iya rage yawan farashin samarwa, ta hanyar rage yawan amfani da kayan, rage haɗuwa da ayyukan gamawa, da haɓaka ƙarfi da tsawon rayuwar sassan.

Yin gyare-gyaren allura tsari ne mai dacewa kuma abin dogaro wanda zai iya biyan buƙatun masana'antu da aikace-aikace daban-daban.Koyaya, gyaran allura shima yana da wasu ƙalubale da iyakoki, kamar:

- Babban saka hannun jari na farko: Yin gyare-gyaren allura yana buƙatar farashi mai girma don ƙira da yin rami, da kuma siye da kiyaye na'urar gyare-gyaren allura.Ƙaƙwalwar ƙira yawanci ana keɓance shi don kowane sashi, kuma yana iya zama tsada da ɗaukar lokaci don samarwa.

- Zaɓin zaɓi mai iyaka: Yin gyare-gyaren allura zai iya amfani da kayan thermoplastic kawai wanda zai iya narke da gudana a ƙarƙashin babban zafin jiki da matsa lamba.Wasu kayan thermoset ko kayan haɗe-haɗe bazai dace da gyare-gyaren allura ba, ko kuma suna iya buƙatar ƙari na musamman ko jiyya don haɓaka gyare-gyaren su.

- Tasirin muhalli: Yin gyare-gyaren allura na iya haifar da zafi mai yawa da kuma fitar da iska yayin narkewa da sanyaya kayan filastik.Yin gyare-gyaren allura kuma na iya samar da sharar filastik daga abin da ya wuce gona da iri wanda ke fita daga cikin kogon gyaggyarawa ko kuma ya yi gefuna na ɓangaren.Waɗannan kayan sharar suna buƙatar sake yin fa'ida ko zubar da su yadda ya kamata, don rage tasirin muhallinsu.

Yin gyare-gyaren allura wani tsari ne mai rikitarwa kuma mai ƙarfi wanda ke buƙatar tsarawa, ƙira, da ingantawa.Injiniyoyi gyare-gyaren allura suna buƙatar la'akari da abubuwa da yawa, kamar:

- Zaɓin kayan aiki: Zaɓin kayan filastik yana rinjayar kaddarorin, aiki, bayyanar, da farashin ɓangaren ƙarshe.Kayan filastik yakamata ya dace da buƙatun aikin ɓangaren, muhalli, ƙayatarwa, da dorewa.Abun filastik kuma yakamata ya kasance yana da kyakkyawan zazzaɓi, kwanciyar hankali, raguwa, da dacewa tare da ramin ƙira.

- Ƙirar ƙira: Ƙirar ƙirar ƙira ta ƙayyade siffar, girman, inganci, da rikitarwa na ɓangaren ƙarshe.Ramin ƙura ya kamata ya sami isassun isassun iska, sanyaya, fitarwa, da tsarin matsawa, don tabbatar da ingantaccen tsarin allura mai santsi da inganci.Haka nan rami ya kamata ya kasance yana da kusurwoyi masu dacewa, kaurin bango, juriya, da ƙarewar saman, don hana lahani da nakasu a ɓangaren ƙarshe.

- Ma'auni na tsari: Saitunan tsarin allurar suna shafar halayen kwarara, ƙimar sanyaya, rarraba matsa lamba, da crystallization na kayan filastik.Ya kamata a daidaita sigogin tsari don haɓaka cikawa, tattarawa, riƙewa, sanyaya, da fitar da matakan aikin allura.Hakanan ya kamata a kula da sigogin tsari da sarrafawa don kiyaye daidaito da inganci a cikin samfurin ƙarshe.

Yin gyare-gyaren allura wani tsari ne mai ƙarfi kuma sanannen masana'anta wanda zai iya ƙirƙirar sassa na filastik masu inganci tare da siffofi da ayyuka daban-daban.Yin gyare-gyaren allura yana taka muhimmiyar rawa a masana'antu da yawa waɗanda suka dogara da samfuran filastik don aiki da riba.Yin gyare-gyaren allura kuma tsari ne mai ƙalubale da haɓakawa wanda ke buƙatar sabuntawa akai-akai da haɓaka don saduwa da canje-canjen buƙatu da tsammanin abokan ciniki.